Component safety

Safety is of the utmost importance for the long-term and economical operation of components and welded structures. To protect people and the environment, the legislature specifies guidelines for pressure equipment (PED) and construction products, among other things. The avoidance of brittle fracture is particularly important for component safety.

Basically, a component is classified as safe if the loads (impacts) that occur are permanently lower than the resistance of the material to fracture.

The following applies: action S < Resistance R (limit state equation)

Cracks impair component safety, but they are not generally classified as a safety hazard. Only when cracks reach a critical size does failure occur due to crack initiation. This event can be estimated mathematically using fracture mechanics methods. Statements about a further service life are also possible.

We have over 30 years of experience in applying fracture mechanics methods for safety analysis according to general standards such as BS 7910 or API572 or the FKM guideline. We also perform calculations within the framework of EN 1993-1-10 Method 2 (Eurocode 3) and EN 13445 or EN 13480, Part 2, Annex B, Method 3 (pressure vessels and pipes). Numerous buildings and welded constructions were preserved in this way.

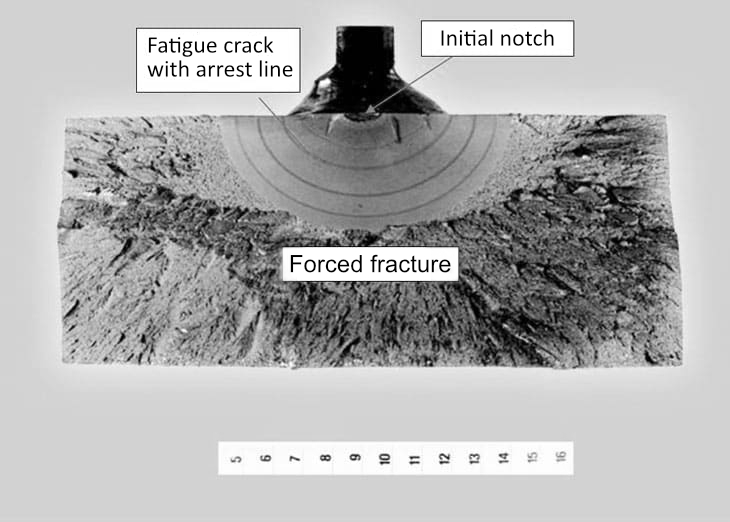

Brittle fracture at T = -100 °C after fatigue cracking.

Forced fracture starting from fatigue crack at room temperature

“Living with cracks” is that even possible?

Yes, using fractional mechanics.

Fracture mechanics methods have been processed over the last 40 years in extensive international studies, in which IWT has also been involved since the 1990s, to such an extent that they can be used in practice. Classic examples of applications are nuclear technology and the aerospace industry. The development of transfer models such as the Master Curve concept now allows a pragmatic and economical application in the conventional industrial areas of steel construction, pressure vessels, pipelines, shipbuilding, wind energy and mechanical engineering.

As known from the strength analysis, the fracture-mechanical safety analysis includes the calculation of the crack stress from external and internal stresses on the component side and the determination of fracture toughness parameters with the help of laboratory samples on the material side. The fracture-mechanical safety analysis is used for static, cyclic and dynamic load cases.

IWT has many years of expertise in this technical application and therefore gives you a pragmatic approach to the application of fracture mechanics. We adapt your problem to the possibilities of fracture mechanics with the aim of obtaining an economical and safe solution.

We are networked with the leading fracture mechanics experts in Germany and are members of the Fracture Working Group of the German Association for Materials Testing and the German Society for Materials Science. This enables us to solve even the most complex problems.

Typical areas of application for fracture mechanics testing and safety analysis are:

- General: welded constructions and cast components

- Aerospace Engineering

- Off-shore and wind turbines

- Rails and rolling stock

- Bridges and other steel structures

- Pressure vessels, pipes, fittings and pipeline

- Shipbuilding

- Heavy engineering

- Construction machinery

FAQ

Is a component with a crack still safe to operate?

How much time remains until a crack becomes critical and leads to collapse?

The determined Charpy toughness is lower than the standard requirement. Is the component still safe?

What is the toughness requirement for low-temperature applications for new steels or for welded joints?

Selected example projects

Sorry, no posts matched your criteria.