Damage Analysis

We carry out damage analyses on metallic components according to VDI guideline 3822.

We combine the results of the analyses systematically and with material-technical competence in search for the cause. We do this in most cases by taking design and manufacturing processes as well as stress into consideration.

We are a member of the AG Fractography in the DVM/DGM Joint Committee “Scanning Electron Microscopy in Materials Testing” under the direction of the Federal Institute for Materials Testing (BAM) Berlin.

Method

We carry out damage analyses on metallic components according to VDI guideline 3822.

More about damage analysis

Damage Description

Assessment

Damage hypothesis

Instrumental analyses

Investigation results

Cause(s) of damage

Damage compensation

Report

Knowledge management

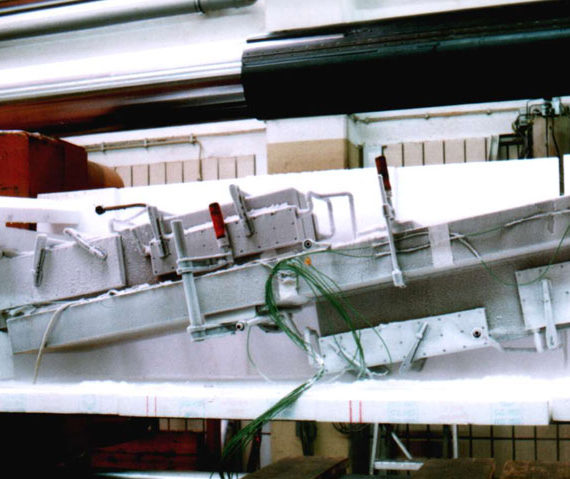

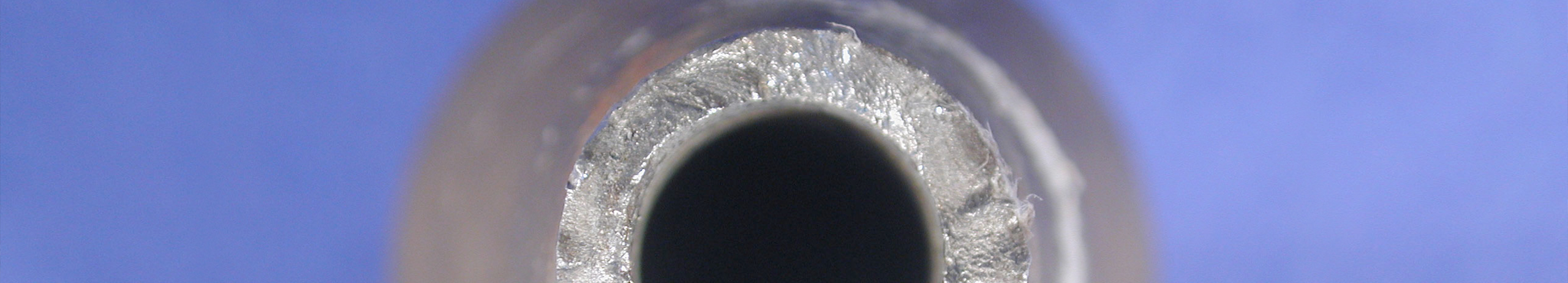

Burst pressure vessel

Selected example projects