Material properties under the influence of hydrogen

With the help of fracture mechanics, the dangers posed by cracks and crack growth can be analysed and the complex and temporal interaction of various load factors can be recorded. This brings the decisive aspect, the avoidance of unstable crack growth, into focus and solutions can be provided in the short term.

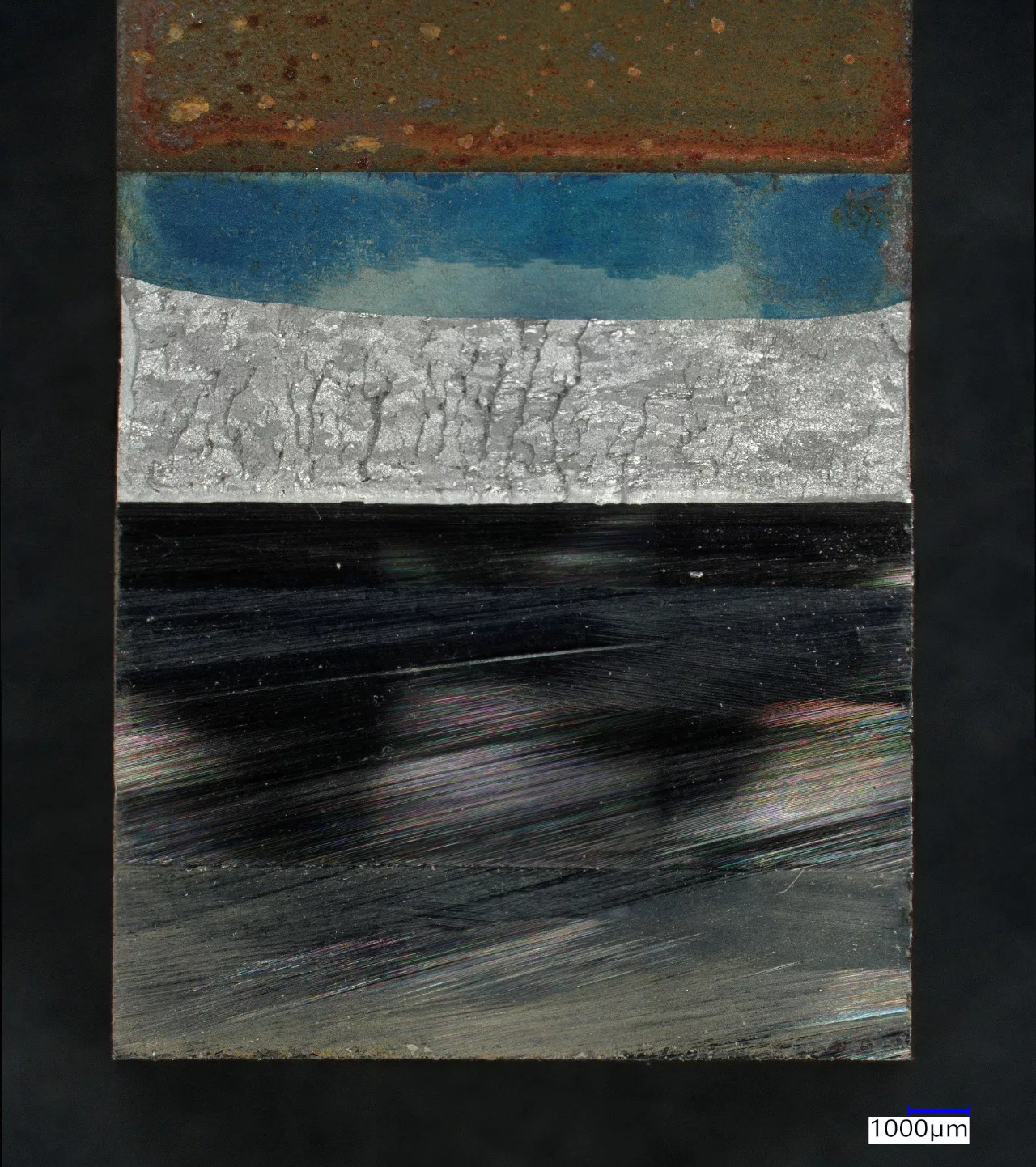

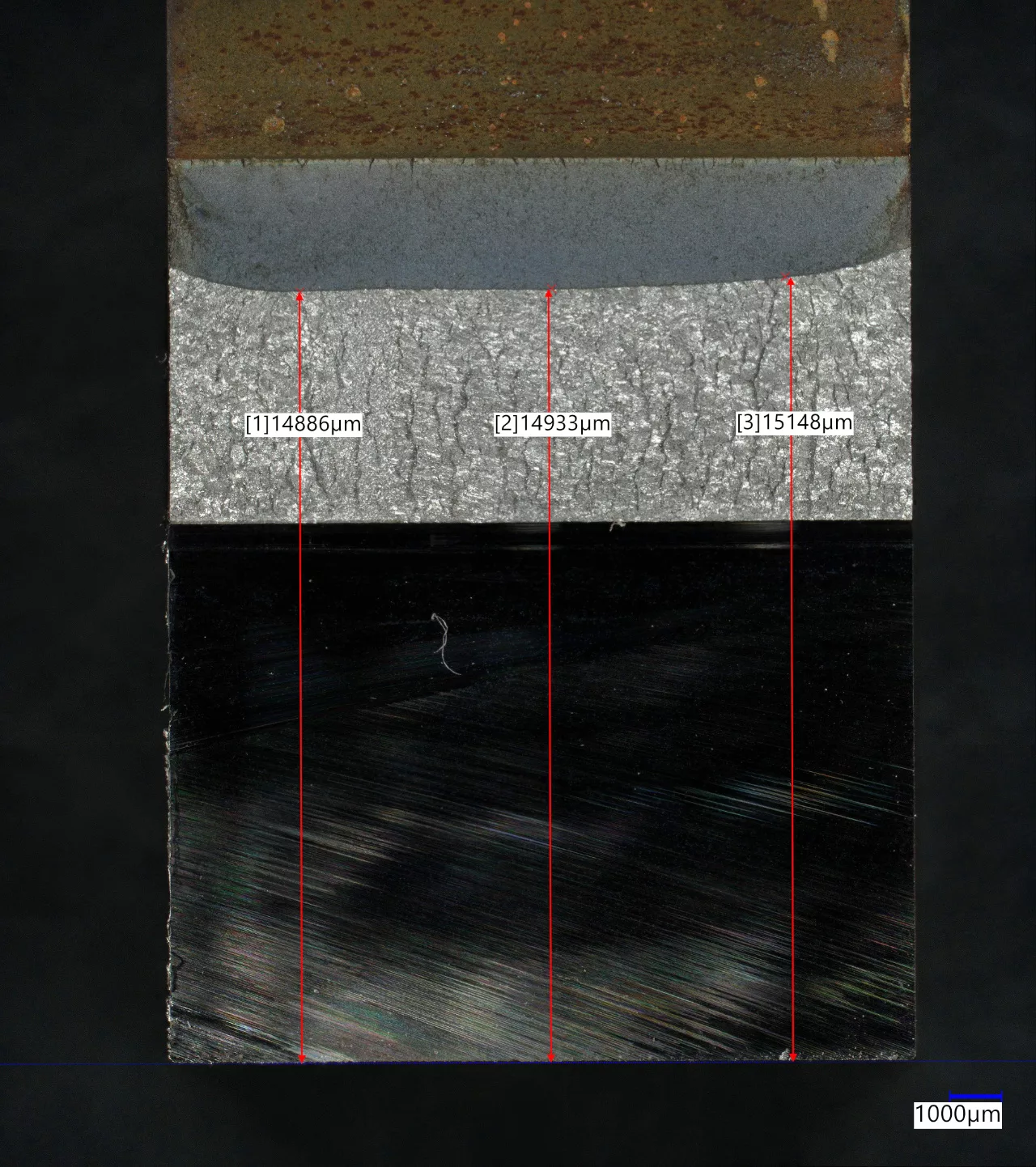

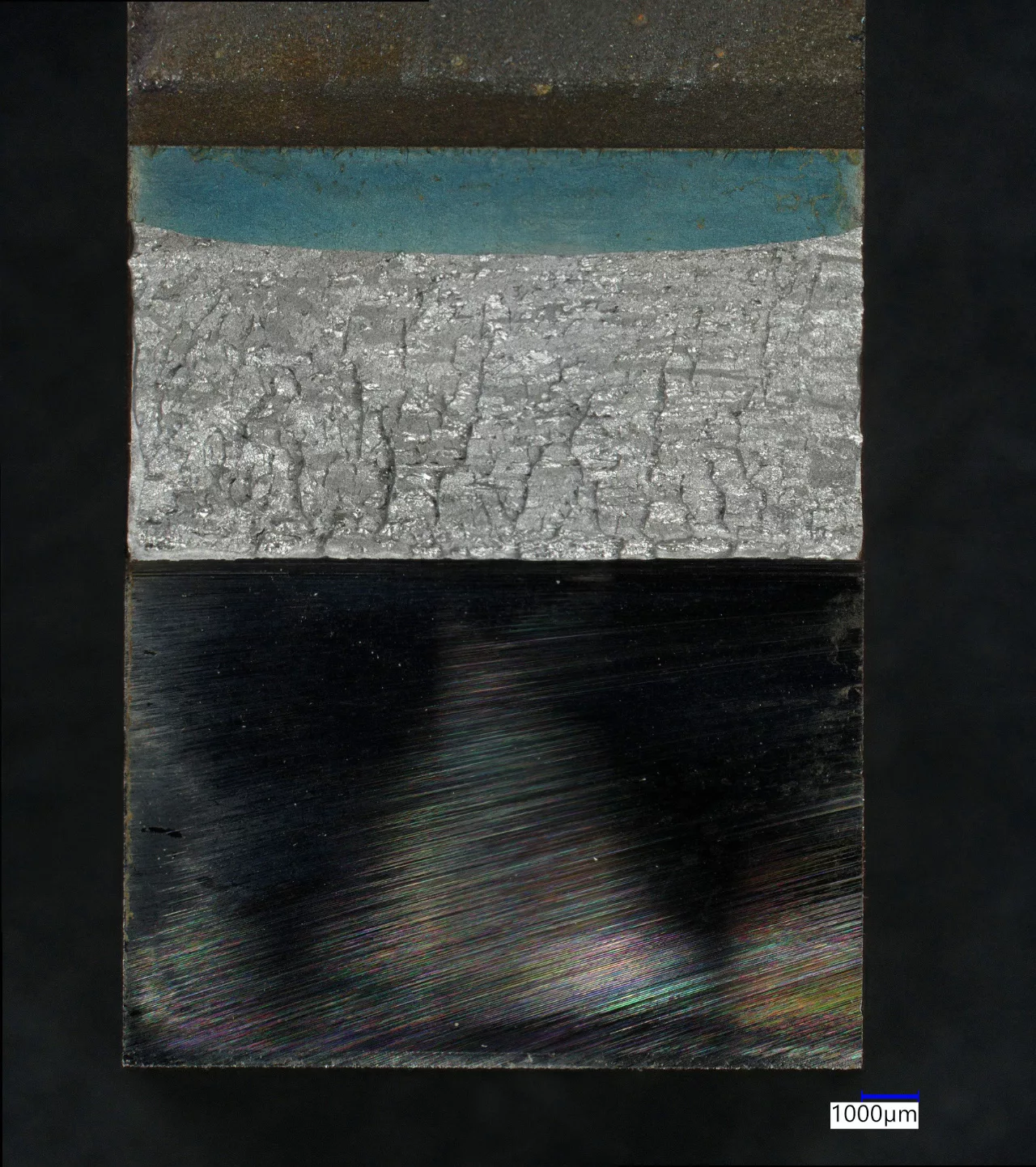

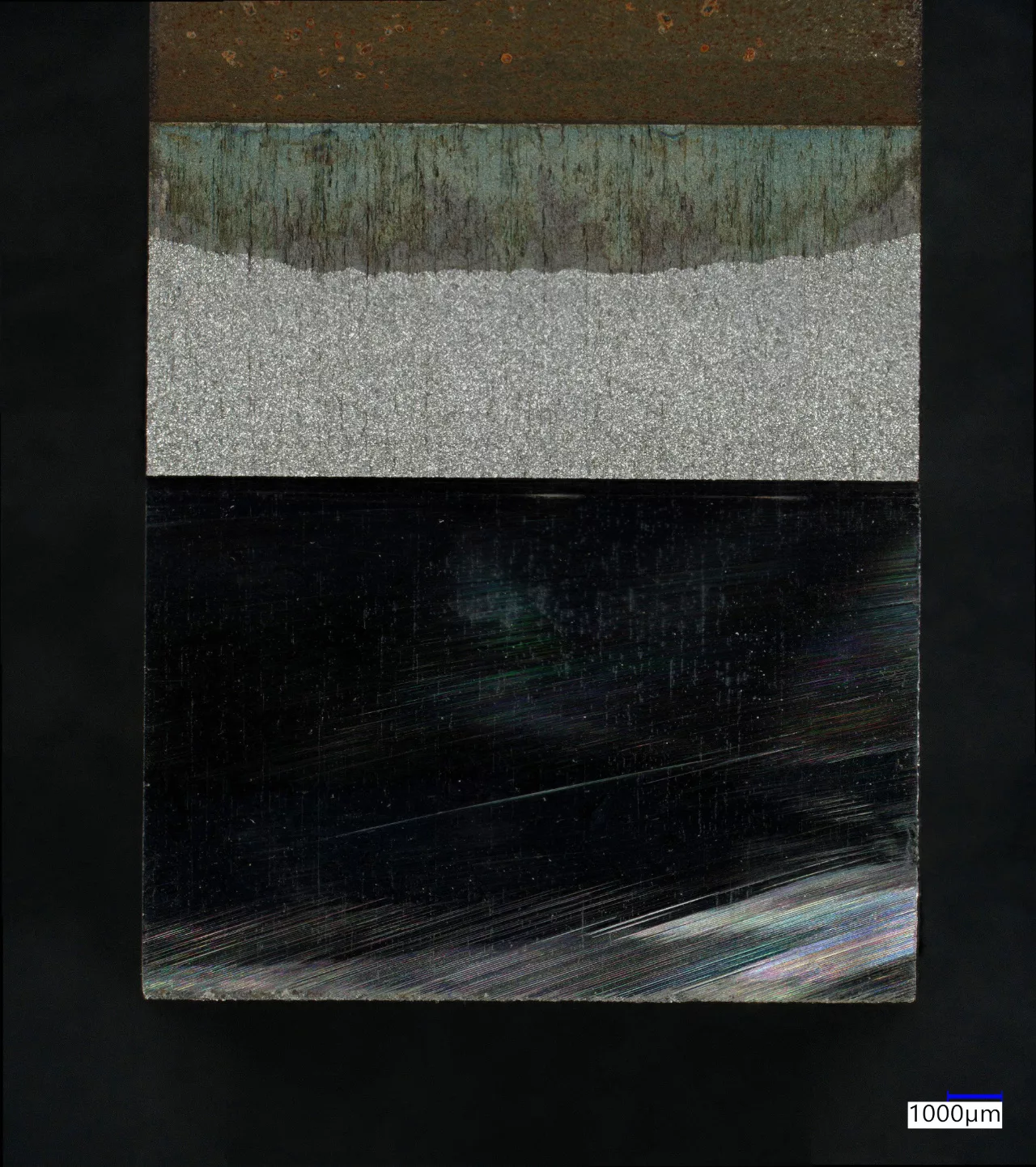

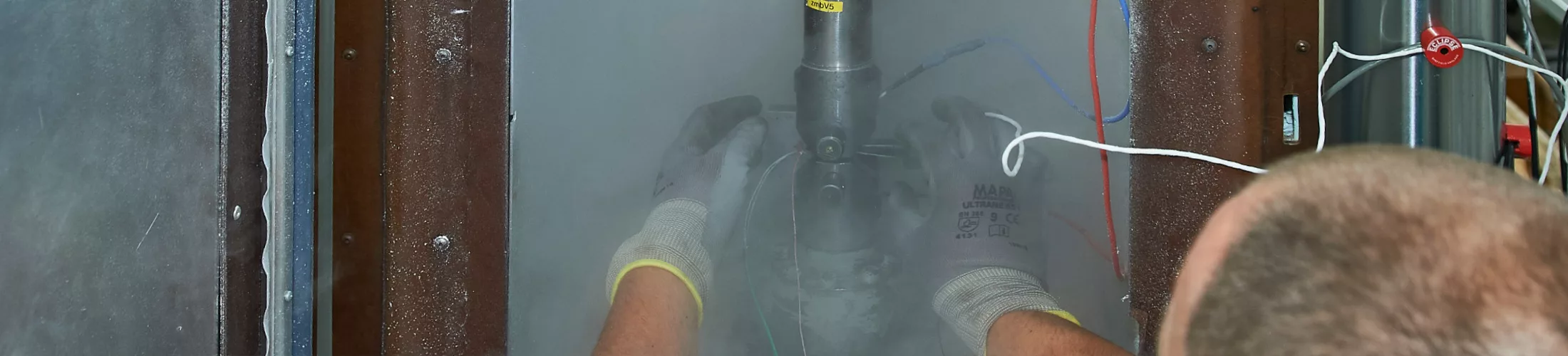

Fracture surfaces of KI,H samples after 1000 hours of exposure to pressurised hydrogen

Especially when using materials in hydrogen media, unstable crack growth and brittle failure is a real hazard due to hydrogen embrittlement. This hazard potential can be evaluated and limited by fracture mechanics tests in hydrogen. Fracture mechanics tests according to the international state of the art (e.g. ASME B31.12) can also be used for the qualification of materials and welded joints as “H2-qualified”. In this way, fracture mechanics in hydrogen, as in other high-security applications such as nuclear technology or offshore oil and gas or pressure equipment, makes an important contribution to safe operation and the avoidance of long downtimes.

More about H2 Qualified

Fracture mechanics tests in hydrogen environment

There are currently two standardised test types for fracture mechanics tests in hydrogen environments:

- The conventional test set-up with CT or SENB specimen in which the fracture toughness is determined according to ASTM E 1820 or a crack propagation curve according to ASTEM E 648.

- The KI,H test according to ASTM E 1681-03 in which a special fracture mechanics specimen is placed under constant prestress and then aged in an autoclave for a predefined time in a pressurised hydrogen atmosphere. This test is currently also required by ASME B31.13 Option B.